Bob Greenyer has posted a new video where he cracks open the alumina foam housing from the Looking for Heat Model T test bed in which part of the LION 2 reactor has been stuck (LION had sent it to Bob), and carries out a post-mortem.

In the first part of the video Bob shows that some loose material that comes out of the reactor hole, and he notes that there is iron in the Kanthal wire that was used as a heating element in the Model T. He then goes on the crack open the foam to get a look at the remainder of the LION 2 reactor.

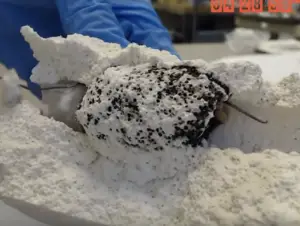

What he reveals is something that looks very different to the control tubes that Alan Smith has been testing on this week. Here are a couple of screenshots of one side of the reactor remains where it looks like the alumina foam has melted onto the reactor:

This shows the other side where the melting has not occurred:

According to this company’s website, the melting point of foamed alumina oxide is 2,072° C (3,762° F). Remember that LION himself, who did this test, stated that this reactor continued to self-sustain at temperatures in the region of 1000 C for about 2 days with the power turned off, but unfortunately we don’t have any detailed data about this event. It will be interesting to see how Alan Smith’s testing of a fueled reactor goes.

The full video of Bob’s excavation is below.

UPDATE (February 15, 2018) I thought I would add what I thought was a very helpful analysis by Russ George from the comments below:

Melting Miasma – The intact Kanthal wire is a witness to the temperature not reaching the melting point of kanthal which is listed as being 1500 C. The alumina block melts above 2000 C, the quartz melts at just under 1700 C. So if the quartz melted likely the kanthal which was in contact with the quartz might be expected to melt, not seen. Surely the alumina foam which was outside of the quartz melting at 2000 C would not ‘melt’ without the intervening kanthal showing melting which would occur at 1500 C. If during the oxidation of the copper that is clearly apparent, that very hot copper oxidation process was capable of perhaps breaking the quartz and that copper oxide invaded the surrounding materials it might well have bonding with all. Copper oxide melts at 1326 C. Copper melts at 1085 C. Nickel melts at 1455 C, don’t forget the tiny 2.5 mm diameter 10 micron thick nickel pads with the diamonds attached to them that are the purported fuel are clearly seen and did NOT melt. Nor did the stainless steel bolt that plugged the reactor tube, stainless steels melt between 1400-1500 C depending on the alloy.

All theses known materials and melting points bear witness to many temperatures that might have been reached in the hot ‘reaction’ zone. In the ‘dummy’ test runs conducted at Alan’s, the maker of the tube furnace test bed, at 1000 C. in these dummy runs without any anomalous fuels, aka the nickel diamond discs, the aggressive hot chemistry of the copper oxide and is very clearly seen. It has fused/bonded itself to the quartz for example. The silver foil that underlaid the copper wire winding at the distal end has a melting point 961 C, is apparent this temperature was reached as the silver appears to have moved by capillary action into the copper/copper oxide material and also appears to have been an effective brazing metal on the quartz, something it is known to do in common practice when making metal seals on quartz lab wear. All, or almost all, the copper was converted to copper oxide at 1000 C, this was not the case in a duplicate test at 800 C where considerable of the copper wire remained as metal though it was oxidized on the surface. The replication with power and thermal data may tell the tale, patience is going to be required before we might make sense of this miasma. Hopefully no one reports seeing the ‘face of Jesus’ in the miasma before the replication and more extensive data is in hand, that would really confuse matters.