The header article for :-

Industrial Heat Amends Answer to Rossi’s Complaint on Aug 11th (Update #2 — Rossi: “The Heat Was Used, Not Vented Away”) quotes IH’s amended answer :-

‘82. … Murray also recognized that the building in which the Plant was located had no method to ventilate the heat that would be produced by the Plant were it producing the amount of steam claimed by Rossi, eonardo, and Penon …’

A bit of a problem here? No, the heat was embodied in hydrocarbon fuels.

‘… such that persons would not have been able to work in the building if the Rossi/Leonardo/Penon claims were true. ‘

Not a problem. ALL heat, bar the last few kilowatts was embodied in hydrocarbon fuels and the ambient temperature would have been fine.

‘This conflicted with the claims of individuals who had been in the building when the Plant was operating, all of whom claimed the temperature in the building was near or not much greater than the outside temperature.’

The ‘claims of individuals’ were correct, in my view.

83. ‘… when in fact it was simply recycling steam from the Plant and sending it back to the Plant as water.’

Doing that would require a condenser to turn the steam into water, which is actually what happens. The issue is what the heat removed by the condenser does and where it goes.

In my view claims 82 and 83 fail.

Overall Thermal Analysis of the Production Plant Process in the 1MW test in Doral, Florida :

Note: All this depends on there being a gas supply.

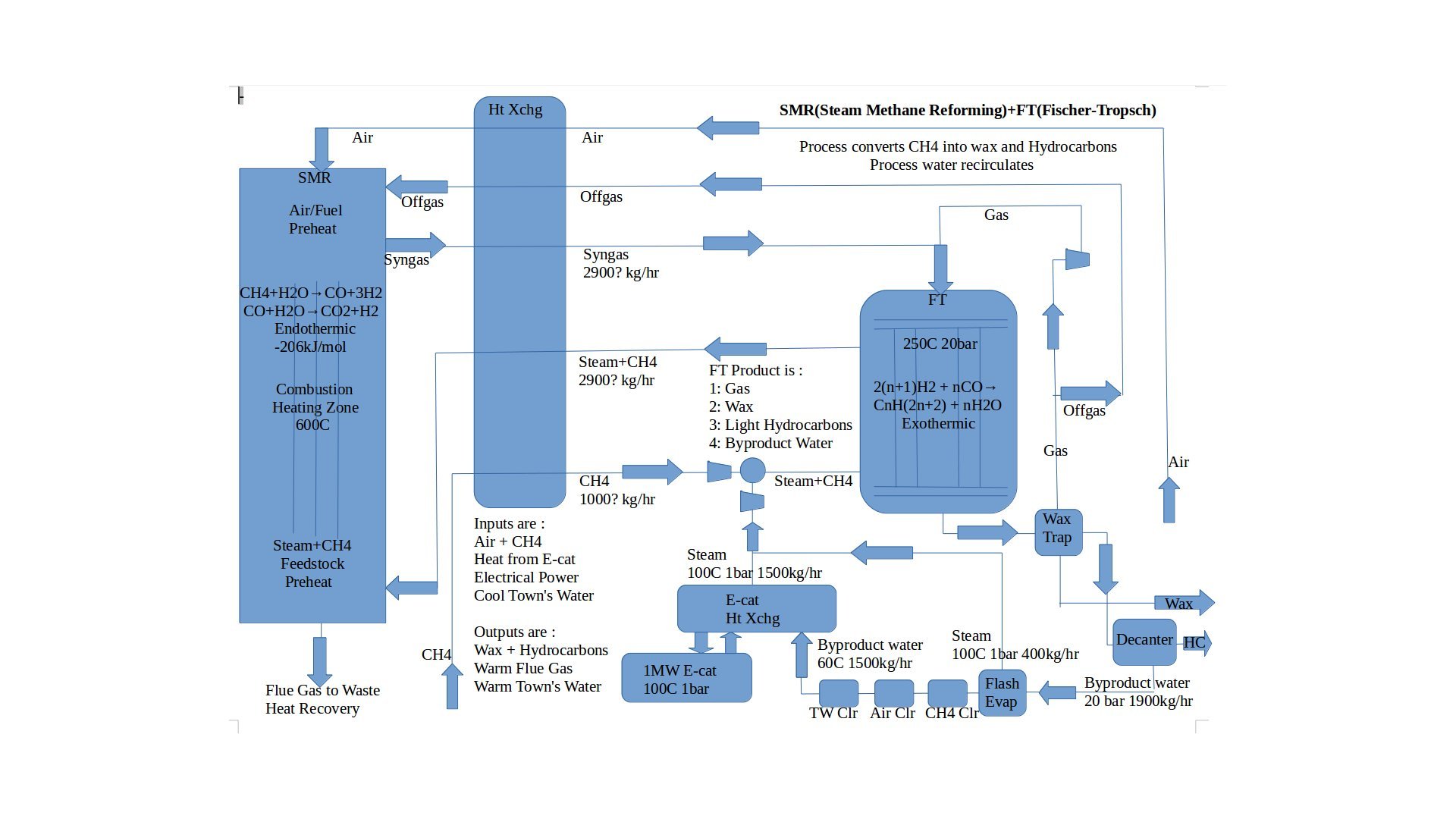

Consider a transport container that contains the whole production process of SMR(Steam Methane Reforming) and FT(Fischer-Tropsch). Another container contains an E-cat producing 1MW of steam and receiving a condensate return flow.

Inputs to the SMR+FT container :

1a: Air for combustion @ 20C

1b: Methane for combustion @ 20C

2: Methane for process raw material @ 20C

3: Towns water for cooling @ 20C

4: E-cat steam that goes to a heat exchanger @ 100C

Electricity to run the plant

Outputs from the SMR+FT container :

1: Flue Gas from combustion @ 60C

2: Liquid+solid hydrocarbons @ 60C

3: Towns water return from cooling @ 60C

4: E-cat return condensate from heat exchanger @60C

Heat loss from container surfaces is zero.

1: The combustion of air and methane is clearly inputting to the SMR+FT container considerable quantities of heat and the flue gases are cool; no different to a domestic central heating boiler. This air flow is taken from the ambient air inside the container and maintains the ambient air at a reasonable temperature. The air eventually emerges from the container via the flue gases, so the container must have a grill through which the outside air can enter when the doors are shut.

2: The methane is the raw material for making the liquid+solid hydrocarbons that are things like diesel, paraffin, avaiation kerosene and solid paraffin wax. They contain a great deal of embodied energy

that can be released by combustion at a later time and another place. These are fuels that are storable and transportable.

3: With so much heat around there is going to be a need for some cooling by air or water at 20C. How much cooling? Perhaps 20kw for the water.

4: The E-cat supplies 1MW of net enthalpy.

Where did the 1MW of heat from the E-cat (and more from the combustion) go?

Into the liquid+solid hydrocarbon fuels where it is stored.

Where did most of the mass of methane go?

Into the liquid+solid hydrocarbon fuels where it is stored. Some went up the flue gas pipe as combustion products.

How much heat was released into the Doral factory?

About 20kw via the town’s water cooling return and that went into the drains, so nothing escapes into the building, except perhaps in a bit of warmth in the liquid+solid fuels that are made. Even the heat from the

lights inside the SMR+FT container goes into the liquid+solid fuels.

Now you know why IH are on a hopeless quest to find a heat signature, except perhaps from the flue pipe and that will be as cold as the exhaust from my domestic condensing boiler. I have just been outside to check the exhaust pipe of my boiler. It is made of PLASTIC!

Below is a schematic posted in another comment by GiveADogABone (Click here for a full size image)

Thermal Analysis of the Production Plant Process in the 1MW test in Doral, Florida (GiveADogABone)

The header article for :-

Industrial Heat Amends Answer to Rossi’s Complaint on Aug 11th (Update #2 — Rossi: “The Heat Was Used, Not Vented Away”) quotes IH’s amended answer :-

Not a problem. ALL heat, bar the last few kilowatts was embodied in hydrocarbon fuels and the ambient temperature would have been fine.

The ‘claims of individuals’ were correct, in my view.

Doing that would require a condenser to turn the steam into water, which is actually what happens. The issue is what the heat removed by the condenser does and where it goes.

In my view claims 82 and 83 fail.

Overall Thermal Analysis of the Production Plant Process in the 1MW test in Doral, Florida :

Note: All this depends on there being a gas supply.

Consider a transport container that contains the whole production process of SMR(Steam Methane Reforming) and FT(Fischer-Tropsch). Another container contains an E-cat producing 1MW of steam and receiving a condensate return flow.

Inputs to the SMR+FT container :

1a: Air for combustion @ 20C

1b: Methane for combustion @ 20C

2: Methane for process raw material @ 20C

3: Towns water for cooling @ 20C

4: E-cat steam that goes to a heat exchanger @ 100C

Electricity to run the plant

Outputs from the SMR+FT container :

1: Flue Gas from combustion @ 60C

2: Liquid+solid hydrocarbons @ 60C

3: Towns water return from cooling @ 60C

4: E-cat return condensate from heat exchanger @60C

Heat loss from container surfaces is zero.

1: The combustion of air and methane is clearly inputting to the SMR+FT container considerable quantities of heat and the flue gases are cool; no different to a domestic central heating boiler. This air flow is taken from the ambient air inside the container and maintains the ambient air at a reasonable temperature. The air eventually emerges from the container via the flue gases, so the container must have a grill through which the outside air can enter when the doors are shut.

2: The methane is the raw material for making the liquid+solid hydrocarbons that are things like diesel, paraffin, avaiation kerosene and solid paraffin wax. They contain a great deal of embodied energy

that can be released by combustion at a later time and another place. These are fuels that are storable and transportable.

3: With so much heat around there is going to be a need for some cooling by air or water at 20C. How much cooling? Perhaps 20kw for the water.

4: The E-cat supplies 1MW of net enthalpy.

Where did the 1MW of heat from the E-cat (and more from the combustion) go?

Into the liquid+solid hydrocarbon fuels where it is stored.

Where did most of the mass of methane go?

Into the liquid+solid hydrocarbon fuels where it is stored. Some went up the flue gas pipe as combustion products.

How much heat was released into the Doral factory?

About 20kw via the town’s water cooling return and that went into the drains, so nothing escapes into the building, except perhaps in a bit of warmth in the liquid+solid fuels that are made. Even the heat from the

lights inside the SMR+FT container goes into the liquid+solid fuels.

Now you know why IH are on a hopeless quest to find a heat signature, except perhaps from the flue pipe and that will be as cold as the exhaust from my domestic condensing boiler. I have just been outside to check the exhaust pipe of my boiler. It is made of PLASTIC!

Below is a schematic posted in another comment by GiveADogABone (Click here for a full size image)